Fiber-optic photoacoustic sensor for remote monitoring of gas micro-leakage

Today, gas leaks can cause enormous hazards and pipelines, gas centers, and chemical plants. Therefore, permanent monitoring of gas leaks should be mandatory. So far, various methods such as electrochemistry, multi-walled carbon nanotube, infrared absorption spectrum, and laser spectroscopy have been introduced to detect gas leaks.

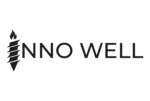

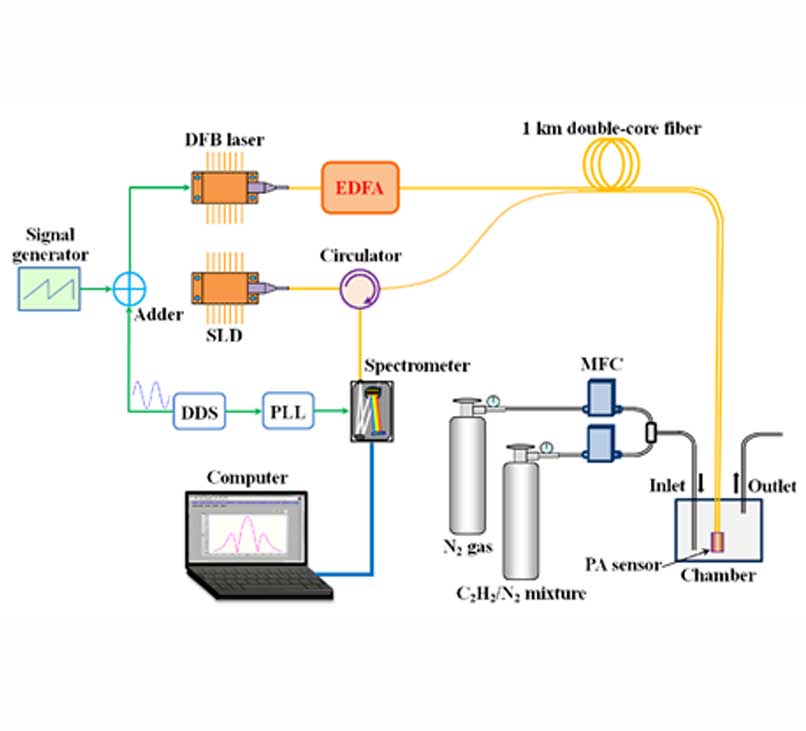

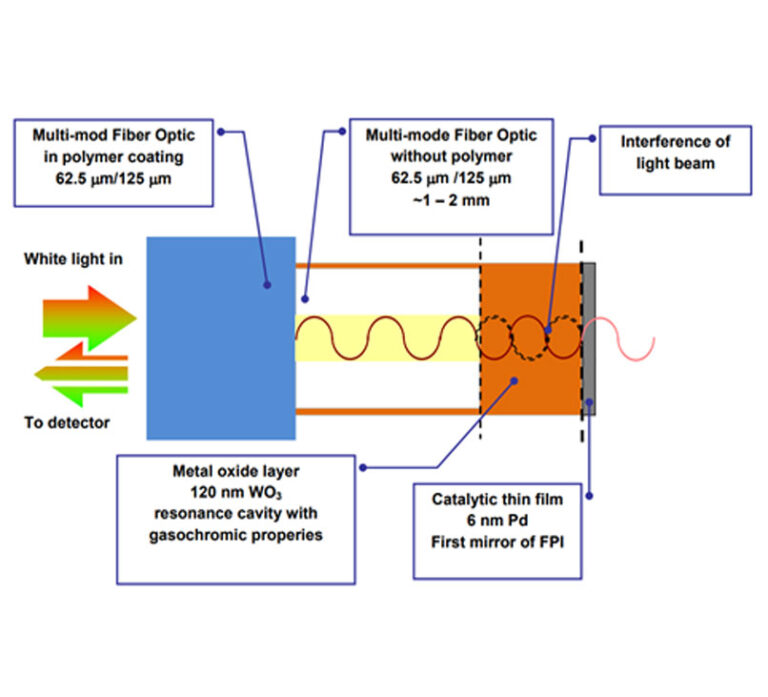

Laser spectroscopy sensors are one of the most suitable options due to remote monitoring, high selectivity, and high sensitivity. The image below shows one of the newest sensors designed based on the mentioned method. The research focuses on developing a fiber-optic gas sensor. The sensor is constructed of an optical fiber.

At the end of the sensor, a tiny ferrule-top PA cavity is placed. The cavity is designed to let the gases in to be measured. The gas deflects a cantilever beam at the end of the sensor, and the laser light emitted from the optical fiber measures the amount of this deflection.

The tests show the sensor could adequately transfer the data of a small room placed 1 KM away flawlessly. The sensor also offers excellent linear output for monitoring C2H2 with concentrations less than 100 ppm.

Furthermore, the results show the sensor response time is 11.2 seconds that is quite fast compared, and the ability to continuously monitor the gas has been confirmed. These developments signal a bright future for the fiber optic sensor industry.

InnoWell is an innovative company in the field of the optical gateway and fiber-optics-based sensors. The various products of InnoWell can fulfill customers’ requirements for measuring temperature, and types of gasses, whether they are toxic or explosive in oil wells, besides identifying gas kick before occurrence.

Copyright © 2023 InnoWell. All Rights Reserved