Low-Frequency Distributed Acoustic Sensing for Early Gas Detection in a Wellbore

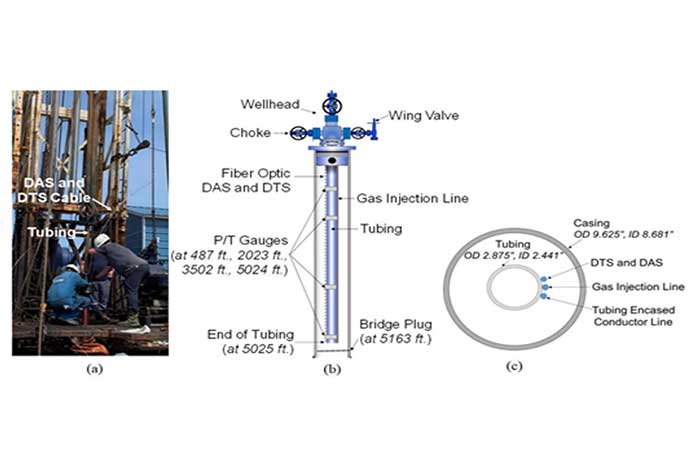

Fiber optics has revolutionized the way we monitor oil wells. With the help of distributed acoustic sensing (DAS), it is now possible to detect gas kicks in oil wells before they cause significant financial and human losses. DAS utilizes low-frequency acoustic waves to detect even small gas volumes in a wellbore.

The use of fiber optics for distributed acoustic sensing has been proven to be an effective tool for early gas detection. By using fiber optic cables, acoustic waves can be transmitted over long distances with minimal loss of signal strength. This makes it possible to detect gas kicks from a distance, allowing operators to take preventive measures before an incident occurs.

Distributed acoustic sensing with fiber optics is an effective way to monitor oil wells and prevent costly incidents from occurring. By utilizing this technology, operators can ensure that their operations are safe and efficient at all times.

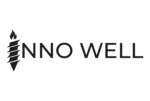

Low-frequency distributed acoustic sensing (DAS) has become a popular method for early gas detection in wellbores. This technique uses two sensors, a distributed temperature sensor (DTS) and a distributed acoustic sensor (DAS), which are inserted into the well in the direction of the drilling tool. The sensors measure the temperature and strain of the well to detect any changes that may indicate a gas kick.

The output results of these two sensors are compared with the temperature-strain patterns when a gas kick occurs, and if they match, an alarm is triggered to warn of a potential gas kick. This method has been proven to be effective in detecting gas kicks before they occur, allowing operators to take preventative measures before any damage can be done.

In addition, to its effectiveness, DAS has also been praised for its use of fiber optic sensors. Fiber optic cables are used to connect the DTS and DAS sensors to the surface equipment, allowing for more accurate data transmission over longer distances than traditional electrical cables. This makes it easier for operators to monitor their wells from afar without having to worry about signal interference or data loss.

Overall, low-frequency distributed acoustic sensing is an effective tool for early gas detection in wellbores, and its use of fiber optic technology makes it even more reliable and efficient. With this method, operators can rest assured that their wells are being monitored closely and any potential issues can be addressed quickly before they become serious problems.

InnoWell is an innovative company in the field of the optical gateway and fiber-optics-based sensors. The various products of InnoWell can fulfill customers’ requirements for measuring temperature, and types of gasses, whether they are toxic or explosive in oil wells, besides identifying gas kick before occurrence.

Copyright © 2021 InnoWell. All Rights Reserved