Parts-per-billion-level detection of hydrogen sulfide based on near-infrared all-optical photoacoustic spectroscopy

Hydrogen sulfide is a colorless, explosive, and toxic gas that smells like rotten eggs. It can cause many side effects such as dizziness and irritation of the respiratory tract. The National Institute for Occupational Safety and Health (NIOSH) has declared the permissible level of this gas to be ten parts per million (ppm). Therefore, the identification of this gas is doubly essential.

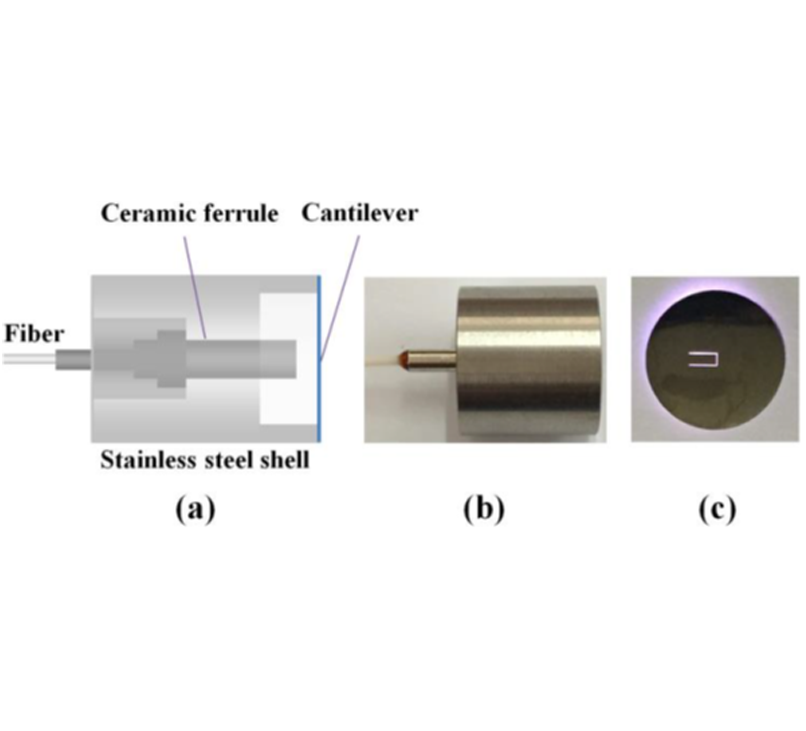

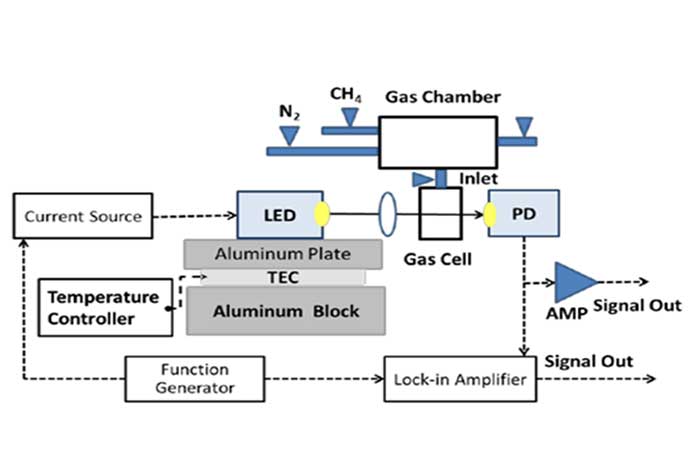

Researchers have developed a new method for detecting hydrogen sulfide at parts-per-billion (ppb) levels using near-infrared all-optical photoacoustic spectroscopy. This method uses an erbium-doped fiber amplified near-infrared laser as the optical fiber light source. A fiber-optic cantilever microphone measures the second-harmonic photoacoustic signal, equipped with a white-light interferometric readout. A virtual lock-in amplifier processes the demodulated digital photoacoustic signal to improve the sensor’s sensitivity.

The detection limit achieved by this method is 33 ppb with a 10-second measurement time at the wavelength of 1576.29 nm. The input and output light of the sensor are both sent by an optical fiber, making it suitable for use in remote sites.

This new method has significant implications for industries that deal with hydrogen sulfide, such as oil and gas production, wastewater treatment plants, and chemical manufacturing facilities. It provides a reliable and efficient way to detect hydrogen sulfide at low levels, ensuring worker safety and preventing environmental damage.

InnoWell is an innovative company in the field of the optical gateway and fiber-optics-based sensors. The various products of InnoWell can fulfill customers’ requirements for measuring temperature, and types of gasses, whether they are toxic or explosive in oil wells, besides identifying gas kick before occurrence.

Copyright © 2023 InnoWell. All Rights Reserved